The Henrico County Water Reclamation Facility (WRF) has become a cornerstone of wastewater treatment in Virginia. Led by Division Director James Grandstaff, who has served in the role for almost 17 years, the facility is dedicated to treating water to meet some of the highest standards in the industry. With a treatment capacity of 75 million gallons per day (MGD), Henrico WRF is an advanced wastewater treatment plant utilizing enhanced nutrient removal technology.

Reflecting on the journey, Grandstaff shares the evolution of the facility and his career. “When I started at the WRF, the big challenge was meeting new regulatory limits on nitrogen and phosphorus. We had to install new technology and develop procedures to meet stringent limits, and we were successful in that effort,” he explains. “For the last decade, my focus has shifted toward employee development and asset management. One of the greatest joys of my role has been watching others step into leadership roles, not only within Henrico County but beyond.”

Innovation plays a crucial role in the success of the Henrico WRF, and Grandstaff has always prioritized staying ahead of emerging technologies. “We are fortunate to work for an organization that supports research and technology,” he says. “We actively engage with industry organizations like the Virginia Water Environment Association (VWEA), the Virginia Biosolids Council (VBC), and others to keep up with the latest advancements in wastewater treatment.”

His commitment to innovation is clear: “We partner with vendors, consultants, and engineers to test new ideas and technologies that can improve our operations,” he adds. “We partner, and we test.” Grandstaff explains, “We use science to determine if the new technology works,” as well as whether the new technology is safe, efficient, and cost effective. “If it checks these boxes and it provides value for Henrico County, we support it – whether it be a new piece of equipment or a new process or procedure.”

As a longstanding member of the Virginia Biosolids Council (VBC), Grandstaff highlights the significance of the organization’s Code of Good Practice, which emphasizes not just regulatory compliance but the proactive improvement of the industry. “The VBC’s role is to educate the public about the science behind biosolids and the benefits of their recycling. We have to do better than just meet regulations—we must build relationships with our communities and regulators to ensure that people understand the value of biosolids,” he notes.

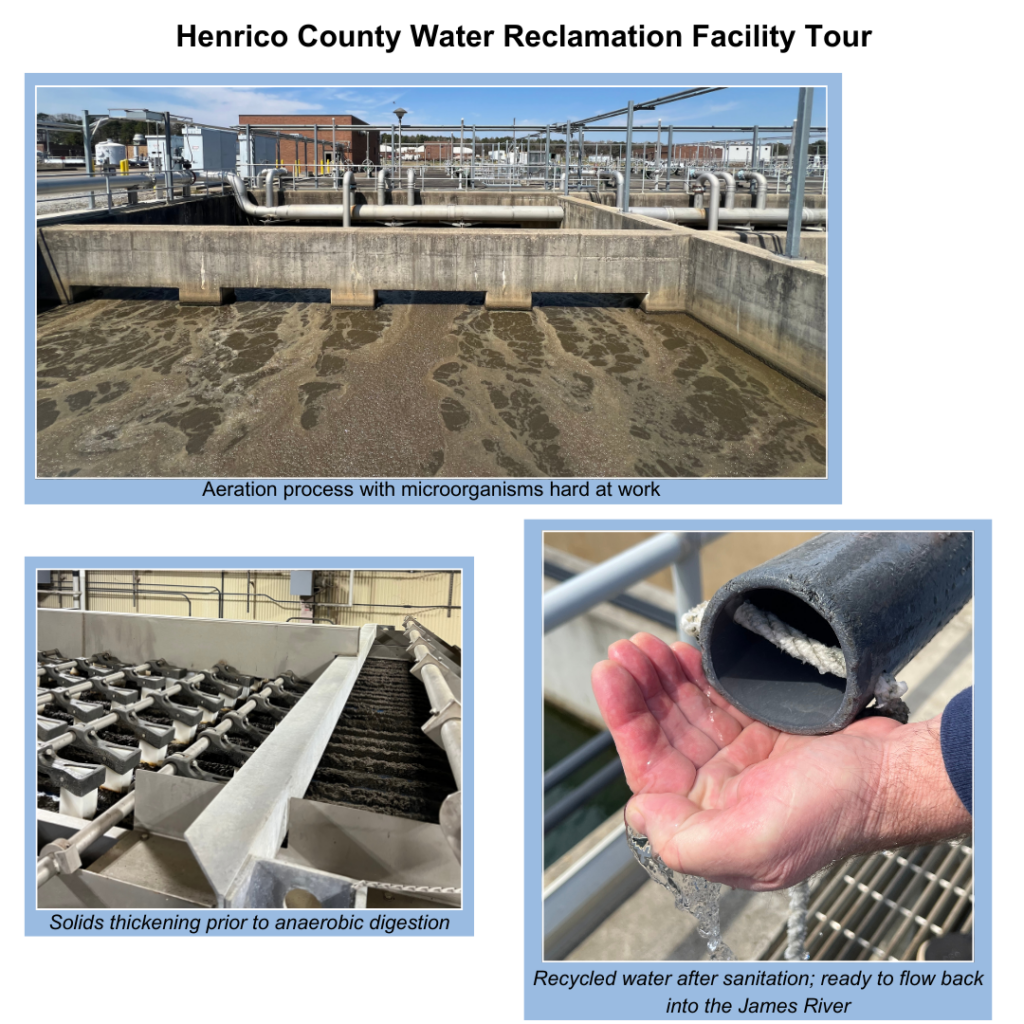

One of the common misconceptions surrounding biosolids is the assumption that they must be harmful because of their odor. Grandstaff dispels this myth, saying, “Biosolids are not ‘poop.’ They are the product of a biological process. The microorganisms we work with are similar to those found in the human gut, and the stabilization process removes harmful pathogens, ensuring safety.”

He further emphasizes the positive environmental impact of biosolids recycling, including its role in supporting agriculture, reducing landfill waste, and promoting soil health. “By recycling biosolids, we’re supporting farmers and maintaining low service rates for residents,” he explains.

During our visit, Grandstaff shared an interesting connection between biosolids technology and human biology. “The microorganisms used in our anaerobic digesters are the same as those found in the human gut,” he laughs. “And just like us, they produce gas. The kids love hearing that part during tours, and I think it helps make the process more relatable.”

The benefits of biosolids recycling go beyond the environment. As Grandstaff notes, “The real value of biosolids recycling is its impact on the community. It supports agriculture, reduces waste in landfills, and ensures that our citizens continue to have affordable services. It’s a win-win for everyone.”

As Henrico County continues to evolve, the Water Reclamation Facility remains at the forefront of innovation in the wastewater treatment industry. Grandstaff’s leadership, combined with the collaborative efforts of his team and community partners, ensures that the facility remains committed to both regulatory compliance and the continuous improvement of operations.

Through his dedication to research, education, and community engagement, Grandstaff has helped shape a facility that not only meets the needs of today but is also prepared for the challenges of tomorrow.